Parts Business

stamping/pressing

Pressing process

PT HK-PATI can accommodate large toner lace machines such as 3000 TRF, 800 TDM, 600 TDM. We have a professional staff with many years of experience and can manufacture products according to your specifications.

welding process

perform the welding process

By actively utilizing simulation technology, HK-PATI is able to mass-produce newly designed parts in a short period of time. Based on our accumulated knowledge and technical data, we plan and construct highly efficient and highly accurate production lines. Furthermore, by sharing and linking product design data between the mold design/manufacturing process, welding line simulation, and robot programming process, the lead time for each process is shortened.

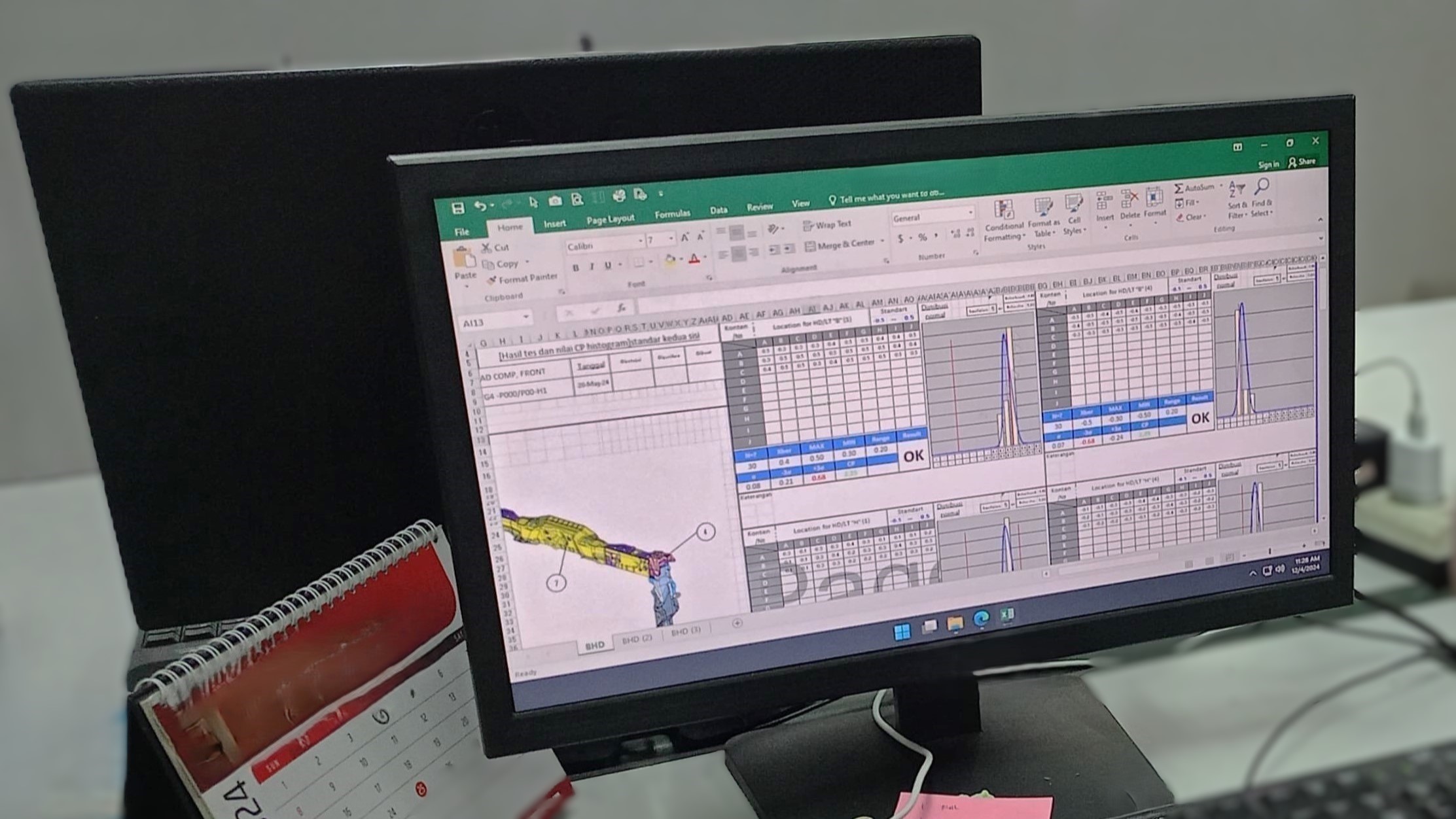

quality control process

quality control process

The quality and safety required for our main products are not only directly linked to the value of our customers' products, but also play an important role in protecting the lives of crew members. Based on this recognition, we always strive to ensure that our customers can purchase our products with peace of mind and use them for a long time. To this end, we have established a basic philosophy as a worldwide quality policy and strive to pursue quality that puts the customer first. Specifically, we conduct quality activities based on a quality management system (QMS) based on ISO9001.

engineering process

engineering process

Hactering is committed to revolutionizing the manufacturing of automobiles and metal parts through innovative engineering processes and artistic techniques. Our commitment to quality and sustainability continues to push the boundaries of what's possible. This document describes the advanced engineering processes and innovative technologies that characterize our company.

Superior strength achieved through innovative advanced technology

Our ultra-advanced steel stamping process is at the forefront of automotive manufacturing. We use advanced materials and precision engineering to create components with unmatched strength and durability. This technology not only improves vehicle safety and performance, but also helps reduce overall vehicle weight and improve fuel efficiency.