Dies Business

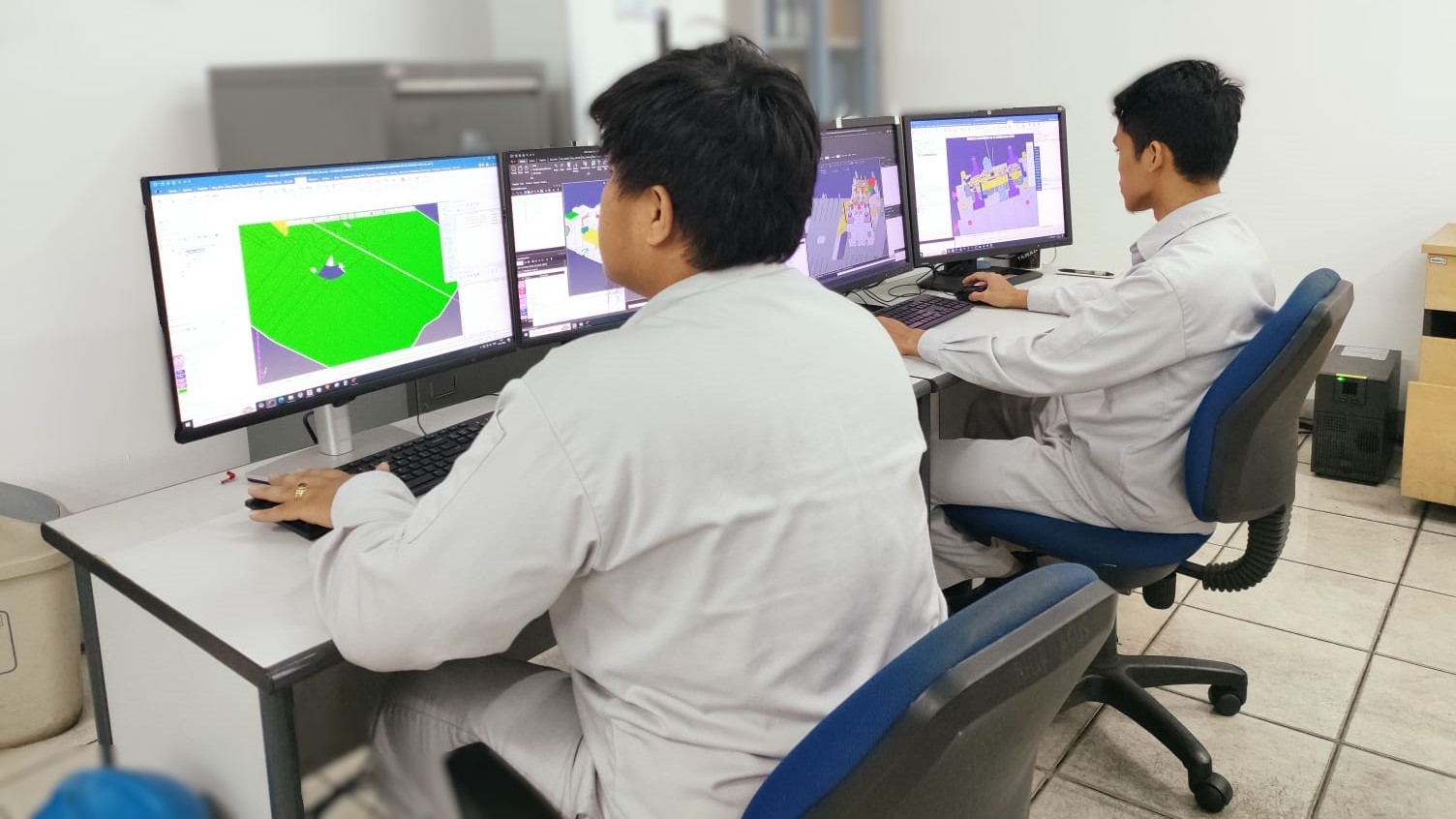

Mold design and CAD/CAM process

Design and data processing

3D 3D design allows you to easily understand part geometry and efficiently check productivity.

3D dimensional design data is used for simulations, robot simulations, mold data, etc., contributing to speeding up product development.

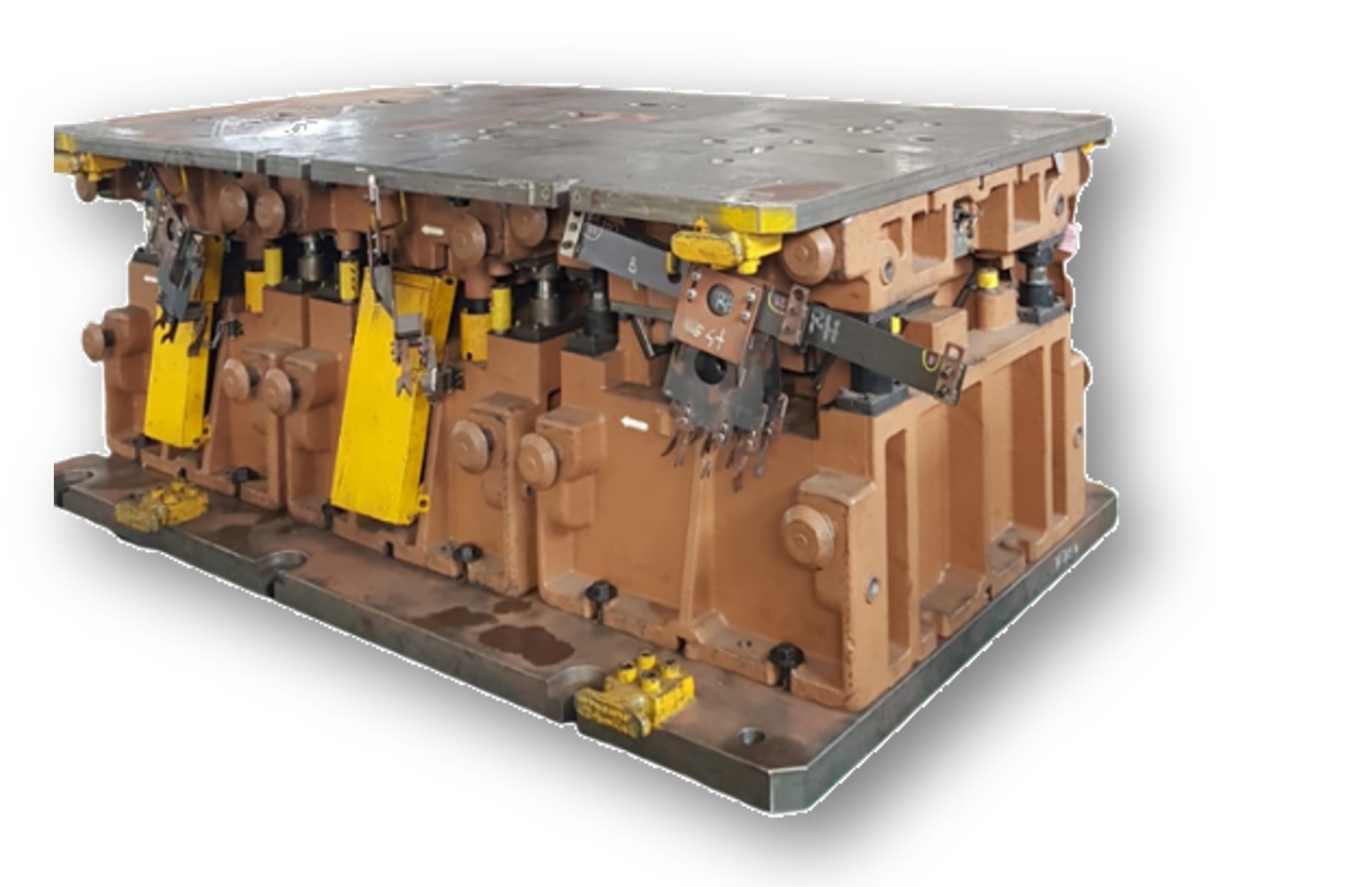

CNC machining

NC machining engineering

The selected materials are processed using various tools and machines such as lathes, milling machines, and grinding machines. Accuracy in this step is critical to ensure tooling and mold features are protected as intended.

We aim to manufacture high-precision molds. We can also produce molds up to 2 x 4 meters. We manufacture molds specialized for processing high-tensile steel plates.

Quality management

quality control process

The quality and safety required for our main products are not only directly linked to the value of our customers' products, but also play an important role in protecting the lives of crew members. Based on this recognition, we strive to ensure that our customers can purchase our products with peace of mind and use them for a long time. To this end, we have established a basic philosophy as a worldwide quality policy and strive to pursue quality that puts the customer first. Specifically, we conduct quality activities based on a quality management system (QMS) based on ISO9001.

Assembly process

Assembly process

HK-PATI tools and molds consist of multiple assembled parts. For tools and molds to function properly, each part must fit perfectly.

Test/inspection

Prototype/inspection flow

Create a prototype, assemble and test the final product.

final product

Finishing process

The final step is complete. This includes tools, molds, and dies that have been polished, coated, or heat treated to improve performance.